Packaging for Medical Devices: Non-Sterile Medical Packaging

Did you know that there are about 2 million different kinds of medical devices worldwide? From simple treatments to complex surgeries, these devices are beneficial for medical procedures. Equally important is the packaging for medical devices.

The design of packaging plays a vital role in ensuring patient safety. While a lot of medical devices need sterile packaging, there are cases when non-sterile packaging is appropriate. Below is a comprehensive guide to designing non-sterile packaging for medical devices.

What is Non-Sterile Medical Packaging?

Want to prevent your medical devices and supplies from contamination? Non-sterile medical packaging stores healthcare supplies that don’t need sterile barrier systems. These products are usually diagnostic or non-invasive, such as:

- Stethoscopes

- Bandages

- Thermometers

- Blood pressure cuffs

- Diagnostic kits

- Medical instruments such as forceps, scissors, tweezers, and scalpels

- Non-sterile dressings, adhesive tapes, and wound cleansers

They’re designed to provide protection and containment for medical items. This ensures their safety during storage, transportation, and use. It also helps maintain the medical device’s integrity until it reaches the end user.

Non-Sterile Packaging vs. Sterile Packaging for Medical Devices

Non-sterile packaging for medical devices and sterile packages differ in several ways. These include:

Sterility

Sterile packaging for medical devices are often designed to maintain an aseptic environment. This prevents the introduction of microorganisms that can contaminate the medical device. However, non-sterile packaging does not provide this level of protection.

Manufacturing Processes

Unlike non-sterile packaging, sterile packaging for medical devices undergo stringent manufacturing processes. These processes often include sterilization methods such as gamma irradiation.

Barrier Properties

Sterile packaging for medical devices has excellent barrier properties. It helps stop the ingress of microorganisms. Additionally, it maintains the sterility of the enclosed medical device.

But, non-sterile packaging only provides basic protection against physical damage.

Intended Use

You use sterile packaging for medical devices that need to maintain sterility until the point of use. These devices include surgical instruments, implants, or disposable medical supplies. However, use non-sterile packaging for medical devices that don’t need sterilization.

A Step-by-Step Guide to Creating Non-Sterile Packaging for Medical Devices

Creating non-sterile packaging for medical devices involves a thorough product development process. Here is a step-by-step guide for creating the packaging:

Step 1: Understand the Requirements

The first step is to identify the specific medical device that needs packaging. It involves assessing the device’s size, shape, fragility, and more. This can help you design packaging that provides adequate protection.

Once you identify the device, review the regulatory standards for medical device packaging. Compliance with regulations such as ISO 11607 allows you to meet quality and safety standards.

Step 2: Packaging Design

To begin, define the primary objectives of non-sterile packaging. When you understand the objectives, you can tailor the packaging design.

Additionally, assess potential environmental stressors, such as temperature, humidity, and more. They help determine the packaging’s durability and ability to withstand different conditions.

Step 3: Material Selection

Non-sterile packaging comprises materials that don’t provide a barrier against microorganisms. As a result, you cannot sterilize them before sealing them. These materials include:

- Bubble wrap

- Paperboard boxes

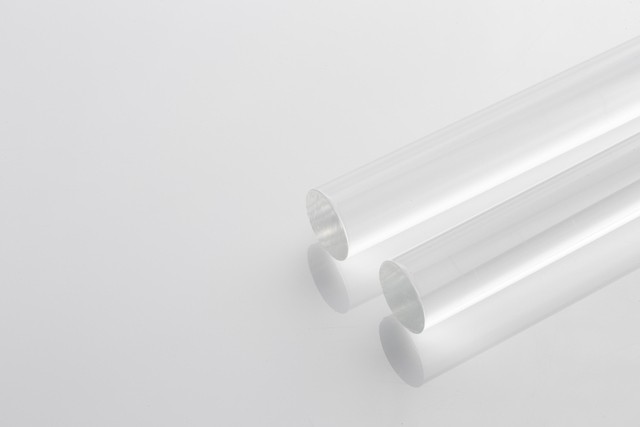

- Plastic Extrusions

- Plastic trays

- Plastic Tubes

- Shrinkwrap

- Stretch film

Selecting the right material is a critical aspect of non-sterile packaging design. Ensure that you choose materials that are compatible with the medical device. They help avoid any compromises in functionality.

Additionally, pick materials that are durable and moisture-resistant. With growing environmental concerns, opt for sustainable packaging materials as well. Consider recyclable or biodegradable options to reduce the environmental impact.

Step 4: Packaging Development Process

The packaging development process ensures the effectiveness of non-sterile packaging for medical devices. To validate the packaging design, develop initial prototypes. These prototypes allow you to assess the functionality of the medical device.

Once you develop the prototypes, test them. Perform compatibility testing. It helps ensure that the packaging materials don’t affect the device’s performance.

Through rigorous testing, you can identify and address any potential issues. Based on the feedback from prototype testing, you can refine your packaging design.

Step 5: Closure Selection

When it comes to non-sterile packaging for medical devices, ensure you find the right closure. You can consider several options, such as:

- Tear notches and slits

- Scoring or perforating

- Press and seal zippers

Choose a closure that’s user-friendly and protects against tampering. It should facilitate a seamless opening process for the end user. What’s more, it should safeguard medical devices.

Step 6: Labeling and Instructions for Use (IFU)

Clear and concise labeling is crucial for non-sterile medical packaging. The labeling should include information such as the product name and device specifications. Incorporating labeling helps ensure information is readily available to the end-user.

You can print the information directly on the packaging material. But sometimes you may need to add labels that are securely attached to the package.

Don’t forget to add the instructions for safe and proper device use. It should be in a language that’s easily understandable by the end-users.

Additionally, you can brand your package with your company’s logo or colors. It can help convey a sense of trust to the end user. Ensure the labels on your non-sterile packaging are resistant to fading or smudging.

Step 7: Validation Trials

Perform validation testing. It ensures that your non-sterile medical device packaging meets all the predetermined objectives. You can also determine if the packaging can preserve the device’s quality.

These trials involve testing the packaging’s durability and performance. Tests you can conduct include:

- Drop Test: Check the packaging’s ability to withstand impacts

- Vibration Test: Simulate various vibration frequencies that the package may encounter

- Compression Test: Assesses the packaging’s resistance to compressive forces

- Environmental Test: Test the packaging’s performance under various environmental conditions

During this phase, you will create a prototype based on the agreed-upon specifications. The prototype will undergo rigorous testing to confirm its suitability.

Step 8: Prototype Approval

After conducting validation trials, you can approve the prototype. Check and assess whether the packaging aligns with your expectations and requirements.

If the prototype is satisfactory, you can proceed with finalizing the packaging design. Additionally, you can prepare it for market release.

Source Quality Non-Sterile Packaging for Medical Devices

When designing non-sterile packaging for medical devices, focus on patient safety. Designing effective packaging requires careful consideration of materials, packaging structure, testing, and more. This can ensure a smooth product development process.

If you are looking for non-sterile packaging, look no further than Petro Packaging. Our products meet all non-sterile medical packaging standards. Request a quote or sample today to get the right packaging.