Stock & Custom Plastic U Channel Extrusions

Plastic U channel extrusions are versatile. They have a multitude of uses within many industries and can be seen daily without you noticing they’re there. These simple shapes are sturdy and long-lasting, making them the ideal material for their intended uses.

Plastic U channel extrusions are versatile. They have a multitude of uses within many industries and can be seen daily without you noticing they’re there. These simple shapes are sturdy and long-lasting, making them the ideal material for their intended uses.

A Choice of Materials

Plastic U channel extrusions can be made in a variety of plastics. Each type has its benefits:

- PETG (Polyethylene terephthalate glycol): Super tough and durable as well as affordable

- CAB (cellulose acetate butyrate): Resistant to ultra-violet rays making it ideal for outdoor applications

- CAP (Cellulose Acetate Propionate): Heat resistant, hard and glossy

Depending on the use of your plastic U channel extrusion, one of the above materials will be better suited to the application.

Applications for Plastic U Channel Extrusions

It’s amazing how versatile this product is and just how often it’s used. Its two main uses, however, are for use in the displays or as a protective element. You will find plastic U channel extrusions used in the following ways:

Protective Applications

- Edge protection: Covering edges such as shelves and displays to stop them from becoming damaged

- Impact protection: Corners or edges that are easily knocked or banged can be protected with this product

- Conductor bar protector: Electrical components will be insulated

- Cable organization: Keep cables and wires tidy and protected

- Bus bar insulator: Electrical components will be insulated

Display Applications

- Label and cardholders: Particularly useful for retail units, a transparent extrusion can be attached to shelves full of products and the price/information labels added behind

- Sign holders: Signs will be protected as well as kept sturdy

- Graphic holders: Great for use in product displays or at trade fairs

- Decorative trim: A tidy and protective way to finish off a display

- Picture Frames: Display important information or images using this sturdy material

- Mirror or display connector: The plastic U channel extrusion can be used to connect display panels or mirrors together to create one large display piece

Industries In Which Plastic U Channel Extrusions Are Found

Given the wide variety of uses for the U channel extrusion, it stands to reason that it can, therefore, be found in a broad range of industries. Some of the biggest consumers of this product, however, are:

- Retail: Given its extended use within displays, the product is most commonly found in the retail industry. Most shelving units in stores will have the U channel extrusion in place to display product information. It can also be found on other hanging displays, graphics, and signage fixtures.

- IT: As plastic insulates electronic components, the U channel extrusion plays an important role in protecting IT and television equipment and keeping the user safe from electrical shocks.

- Trade Shows: Plastic U channel extrusions are usually found connecting and holding trade show displays. Being so lightweight and strong, they’re easily transported and constructed.

- Point-of-purchase (POP): Related to the retail industry, U channel extrusions will be responsible for holding all the displays you see as approach the checkout in a store. Its versatility lends itself well to creating eye-catching features that compel the consumer to buy. Easily constructed and dismantled, the POP display can be changed frequently with minimal effort or cost.

- Office Furniture: Office furniture tends to receive heavy use and is, therefore, more susceptible to damage. Plastic U channel extrusions add a protective edge around desks, units, tables, and other items of furniture to increase their longevity within the office environment.

What Types Of Plastic U Channel Extrusions Are Available?

Petro Packaging Company Inc. is a third-generation, family-run business that specializes in the provision of different types of plastic extrusions and packaging. Our priority is to ensure that we’re offering our customers exactly what they need, so our plastic U channel extrusions are available with a variety of options:

- Our U channel stock PETG plastic extrusions are available in six-foot lengths.

- Our U channel stock CAB plastic extrusions are available in eight-foot lengths.

Both of these options are available for immediate shipping and can be easily cut to size once received.

If you require something a bit different, we also offer custom plastic extrusion services. All you need to do is contact us and we can start the ball rolling by discussing your requirements.

If you’re not sure exactly what would be suitable for your needs, talk to a member of our expert team, and we’ll recommend the right type of plastic U channel extrusion. Whether it’s to protect or display, the Petro Packaging Company Inc. has the best product for you.

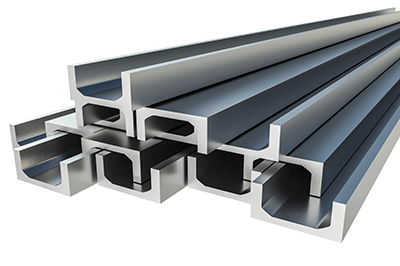

Custom and Stock Plastic H Channel Extrusions

In the world of plastic enclosures and clips, the plastic h channel is the jack of all trades. You find it in more places than we can list here. This makes it a critical buy for any retailer who needs a bag closure, a price tag clip, trim, or any of multiple other uses.

In the world of plastic enclosures and clips, the plastic h channel is the jack of all trades. You find it in more places than we can list here. This makes it a critical buy for any retailer who needs a bag closure, a price tag clip, trim, or any of multiple other uses.

It also means you need to trust where this plastic came from. Petro Packaging Company is proving itself to be a leader in the plastics industry, producing the best custom plastics on the market including the plastic h channel extrusion.

Keep reading to learn more about plastic h channel extrusions and why Petro is your best choice for plastic.

What Are Plastic H Channel Extrusions?

Anytime you see a price tag hanging precariously beneath your favorite at of spaghetti sauce at the grocery store, you’re most likely looking at a plastic h channel keeping that price tag affixed.

The plastic h-channel extrusion is sometimes called the “joiner” channel because it joins the panels of different materials. It can connect plywood, Foamex, surrogate, and a variety of other materials.

The h-channel can be ordered as both a stock plastic extrusion or a custom plastic extrusion. The plastic extrusion process produces a variety of plastic materials. H channel plastic is special because it is shaped like an H.

How Plastic Extrusion Works

The plastic extrusion process starts with a mass of raw plastic in a hopper hanging above a closed channel. The hopper drops the plastic materials into the channel.

Inside the channel is a long screw. The plastic pieces rub against each other as the screw moves them through the channel. The friction along with some external heat causes the plastic to melt into a liquid.

Once the plastic has reached the end of the channel, it is molten plastic and ready for a die. A die is a special tool at the end of the channel that shapes raw materials like plastic into a product like the plastic h channel.

The die is a metal plate cute that has a hole cut in it. The plastic goes through the hole and is shaped into a specific shape. At the end of the die, the plastic comes out as the new, extruded plastic

Then the plastic cools and hardens. Machines cut and prepare the new plastic material, preparing it for shipping or more processing.

What Makes Petro Plastic The Best?

Petro Packaging is the best in the plastics business because of the variety of materials we use as well as the specialization we have. Founded in the 1960s, our company is run by the third generation of our family, making us a reliable, trustworthy company. We’ve weathered the storms of economic ups and downs to become a leading company in the plastics business.

Plus, we offer the most thorough selection of plastic extrusions for whatever applications you need. We are dedicated to processing a variety of materials so we can meet your plastics needs.

Reliable Company

If you have a unique plastic need, Petro wants to help. We specialize in plastic extrusions. This means we understand how to turn basic plastic material into whatever plastic object you need.

You can trust us because we’ve been dominating the plastics industry for over fifty years. We’ve learned to flex with the plastic market and meet the growing demand for plastics materials over the decades.

Plus, we deliver products on time every time. When you put in an order, our engineers work hard to assist you and then ship out our in-stock products within 24 hours of you ordering them.

Specialization

Clear CAB and PETG extrusions are our specialties, but we also provide alternatives such as ABS, styrolus, styrene, and a few other choices.

We have a big inventory that includes all kinds of stock shapes for your display needs. When you have a unique display, we can help make it happen with our POP display plastics.

Customization

We have standard packaging and plastic extrusions as well as customized plastic extrusions. Customization takes up the majority of our manufacturing. We use vacuum and air forming techniques to create anything from basic “U” shaped profiles to more complex configurations.

We have a knowledgeable sales team and engineers that talk you through the process to help you find the best shape and size for your needs. We also have in-house tools and die makers not to mention experienced production personnel that make sure you receive the best item for your needs.

We want to meet your needs from the concept of what you need up to the final product. Our team is here to serve its customers.

Materials

We use the highest quality of PETG Copolymer (Polyethylene Terephthalate Glycol), Clear Tenite CAP, and Tenite CAB plastic. While these are our specialty, we use other materials as well.

Typical plastic h channel extrusions consist of a variety of different materials. These are some of those materials and how they’re used.

- PVC: PVC comes in both firm and flexible grades, clear and opaque. It holds its shape well and yet contours to curved surface areas. It has the best impact strength of all plastics and thus people use it both inside and outside for things like gaskets, edge trims, and retention clips.

- Polycarbonate or PC: You typically see PC used when you need a high-impact resistance material. It has a smooth surface quality as well as colorability. Thus we typically see it used for corner protectors, edge trims, and pricing channels.

- ABS or Acrylonitrile Butadiene Styrene: ABS is a high-impact resistance material that colors well. It has a smooth surface, and we see it most often inside rather than outside.

- Polyethylene (PE0) and Polypropylene (PP): PE is one of the more flexible plastic while PP is the more rigid of these two poly materials. It works best in situations that do not require UV resistance, so we see it in places like bag closure clips, edge trims, assembly magazines, pool liner clips, and wire covers.

- Acrylics: Acrylics work best in situations where clarity and economics are high priority. So you see it with price channels and price tag holders along with bin edging, hinge applications, and shelving edging. It does not absorb impact well.

Trust Petro Packaging and Win

A reliable plastic h channel is one piece of a puzzle in your retail world. It means your price tags stay put or your materials stay joined.

You can trust Petro Packaging Plastic for all of your plastic h channel extrusion orders. If you have questions about our products, contact us. We’d love to help you out.