Extruded rectangular plastic tubing is a game-changer in many industries. Think about a tool that can be custom-made for any business.

It’s used in everything from medical devices to big machines. This tubing is key to making many devices work better.

In this article, we’re diving into the world of this unique tubing. We’ll talk about why its wall thickness matters and how it can be made just for you. This tubing is used in many places, from hospitals to factories.

We’ll show you how it helps in different jobs and why it’s so important. You’ll learn how to pick the right one for your needs.

Join us to see how this tubing isn’t just useful. It’s essential for success and bringing new ideas to life.

Extruded Rectangular Plastic Tubing 101

Extruded rectangular plastic tubing might sound complex, but it’s quite simple. It’s a type of tubing made by shaping plastic into a rectangular form. This process lets us create tubes with precise sizes and shapes.

The first thing to know is what this tubing is made of. Different plastics can be used, each with its own benefits. Some are strong, others can handle high temperatures, and some are even used in medical equipment because they’re safe and clean.

What makes this tubing special? Its shape and size can be customized. This means it can fit perfectly into different machines or devices.

It’s not one-size-fits-all. It’s made to meet specific needs, which is useful in many industries.

Key Characteristics of Plastic Tubing

Wall thickness in plastic tubing is more than a mere measurement; it’s about striking the right balance. A thicker wall means more strength, ideal for heavy-duty industrial use where durability is key.

A thinner wall offers flexibility, essential in spaces where the tubing needs to bend or fit into tighter spots. The choice of wall thickness depends on the specific demands of the application, making it a critical consideration.

Durability in this context means the tubing can withstand regular use without significant wear. This longevity is crucial, especially where frequent replacements are impractical.

Flexibility is equally important. The tubing’s ability to bend without losing strength is invaluable in various applications, especially in compact or dynamic environments.

What sets extruded rectangular plastic tubing apart is its customizability. This feature allows for precise adjustments in:

- Size

- Shape

- Material properties to meet specific requirements

This level of customization ensures that every industry gets exactly what it needs, optimizing both function and efficiency.

Industrial Applications

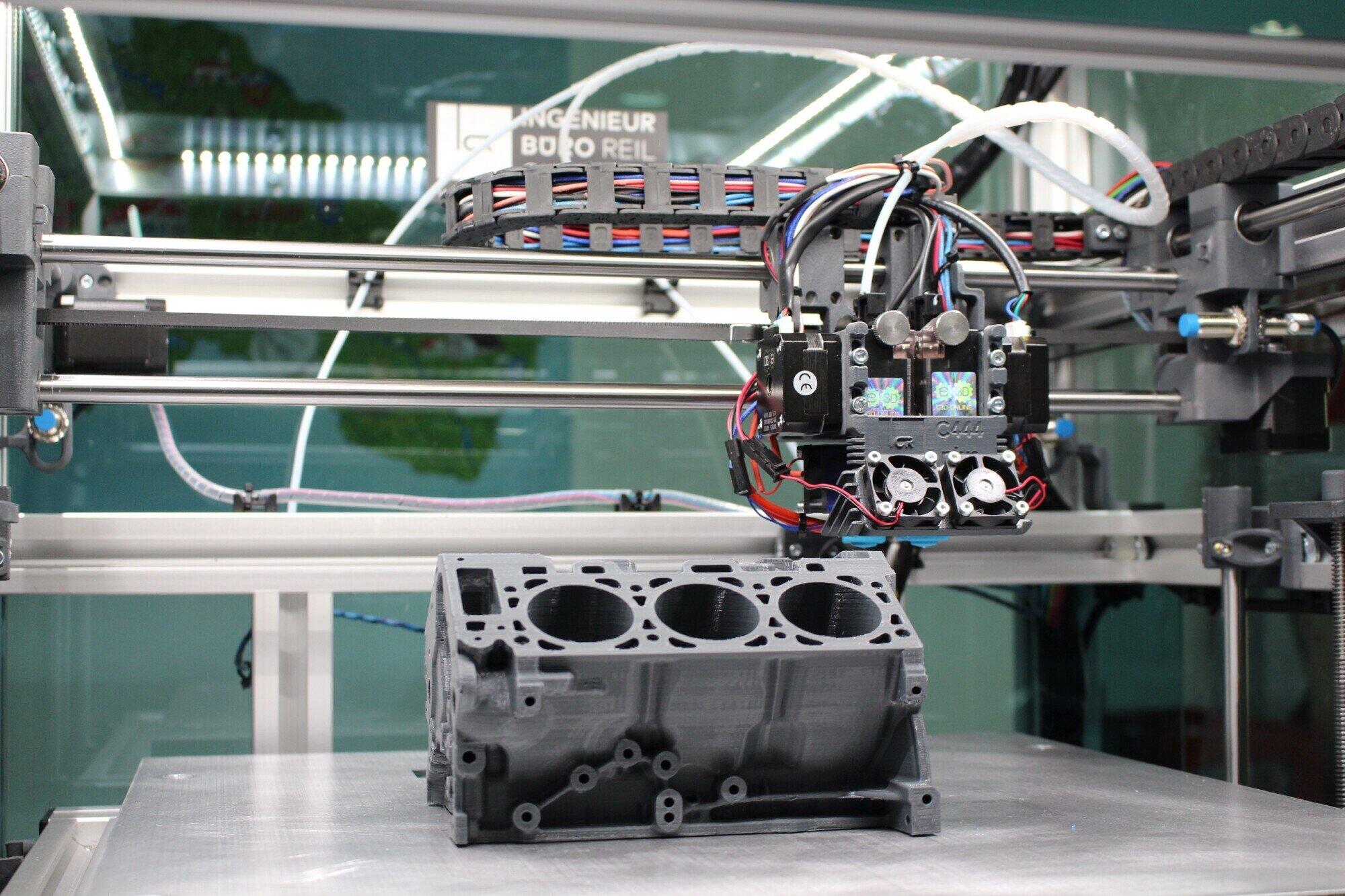

Extruded rectangular plastic tubing has a wide range of applications across various industries. Its unique characteristics make it an ideal choice for many different settings.

In the world of industry, this tubing is a real multitasker. Its strength and durability make it perfect for heavy machinery, where it can handle high pressures and tough conditions. At the same time, its flexibility means it can fit into tight spaces, ideal for complex industrial layouts.

Let’s look at some specific examples. In manufacturing, this tubing can:

- Convey materials

- Protect wires

- Act as part of larger mechanical systems

Its ability to customize in size and shape makes it a perfect fit for specialized equipment.

In the construction industry, the tubing’s robustness is a key asset. It is useful in various applications, from structural components to plumbing solutions. Its resistance to wear and environmental factors ensures longevity, an essential feature in construction.

As technology advances, new uses for extruded rectangular plastic tubing are emerging. Innovations in tubing material and manufacturing processes are opening doors to applications we haven’t even thought of yet.

In every use, the tubing’s ability to tailor for specific needs is a standout feature. Whether it’s a custom size for a unique machine part or a specific material for a medical device, this tubing is all about meeting the exact requirements of each application.

Extruded Plastic Tubing in Medical Devices

Medical devices demand precision, and this tubing delivers it. Manufacturers use it in surgical instruments and diagnostic equipment. They can mold it into exact shapes and sizes for intricate designs.

In complex medical tools, where precision is crucial, every millimeter of the tubing plays a vital role.

In medical applications, safety takes top priority. Manufacturers choose materials for this tubing that are non-reactive and safe for medical use.

These materials comply with strict health and safety standards. They ensure no adverse reactions with medications or human tissue.

Customization is key in medical applications. Different medical devices need tubing with specific properties. For instance, tubing in respiratory machines might need different flexibility compared to that in dialysis machines.

Custom plastic tubing allows each device to function effectively and safely with the exact required properties.

This tubing plays a direct role in patient care. Its reliability and effectiveness influence the quality of medical treatment. Whether delivering medication, assisting in surgeries, or being part of life-support systems, its performance is crucial.

Choosing the Right Tubing for Your Needs

The first step is understanding your application’s requirements.

What will you use the tubing for? Does it need to withstand:

- High-pressure

- Extreme temperatures

- Chemical exposure

The application will determine the material, wall thickness, and flexibility you need.

Different materials offer different benefits. For example, some are more heat-resistant, while others are better for outdoor use.

Consider the environment and the stresses the tubing will face. This understanding will guide you in choosing the right material.

Size and wall thickness are crucial. The right size ensures a proper fit, while the right wall thickness provides the necessary strength and flexibility. Consider the space where you’ll use the tubing and the type of stress it will endure.

Always prioritize quality and compliance with industry standards. High-quality tubing will last longer and perform better. Ensure the tubing meets any necessary regulations, especially for critical applications like medical or food processing.

Petro Packaging: The Path to Efficiency and Innovation

Extruded rectangular plastic tubing is a catalyst for efficiency and innovation across various industries. Its versatility, adaptability, and customization options make it an invaluable asset in meeting diverse operational challenges.

Looking to leverage these benefits for your business? Turn to Petro Packaging for high-quality, customized extruded rectangular plastic tubing solutions. With their commitment to excellence and customer satisfaction, Petro Packaging ensures you receive tubing that perfectly aligns with your specific needs.