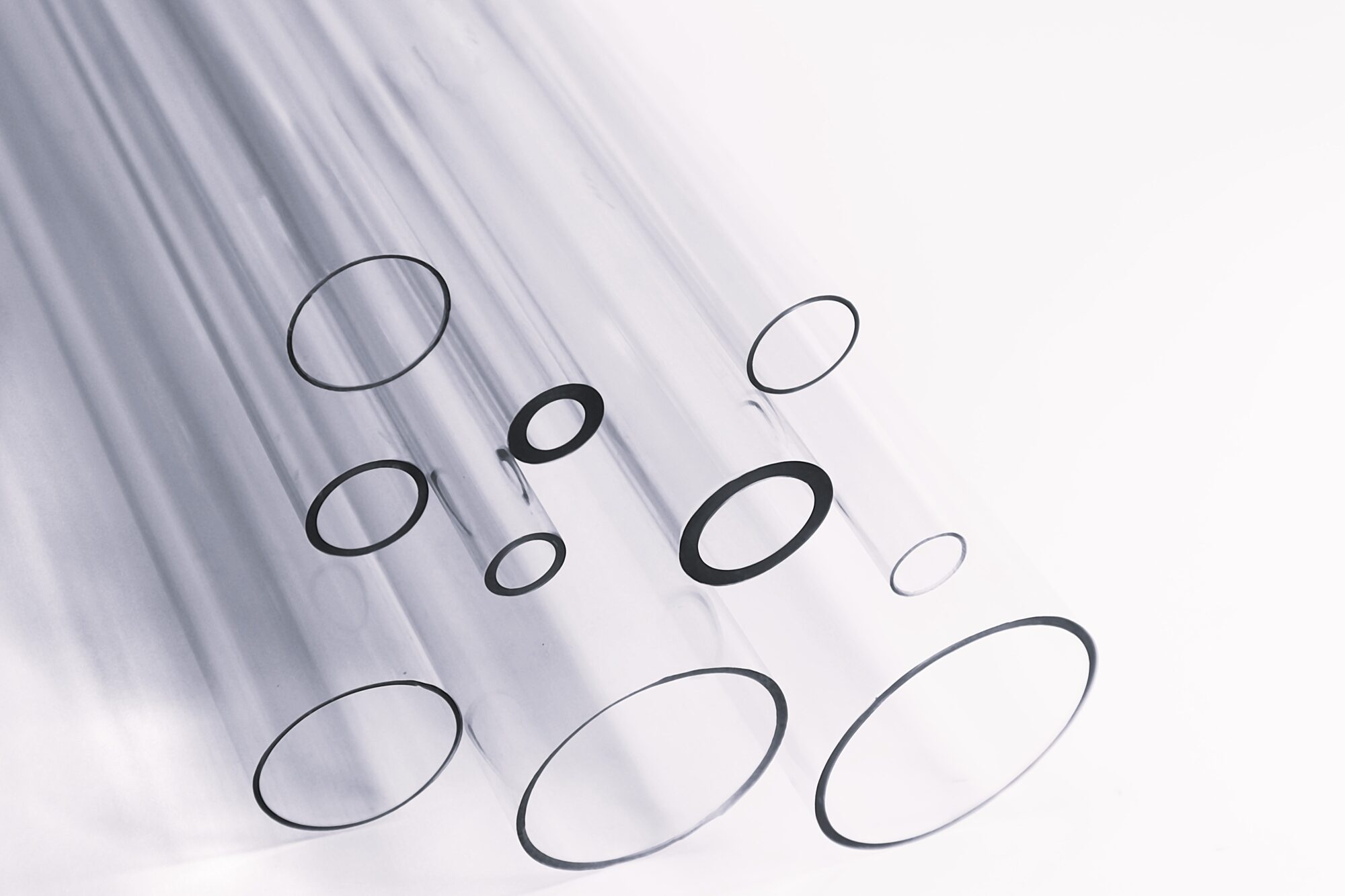

Printing and Labeling

Many consumer products designed for retail display require some form of brand recognition and identification. Company logos, insignias, and product instructions provide the information necessary to promote your product at the point of purchase. Add these valuable pieces of information to your plastic tubes by utilizing our offset printing or labeling capabilities.