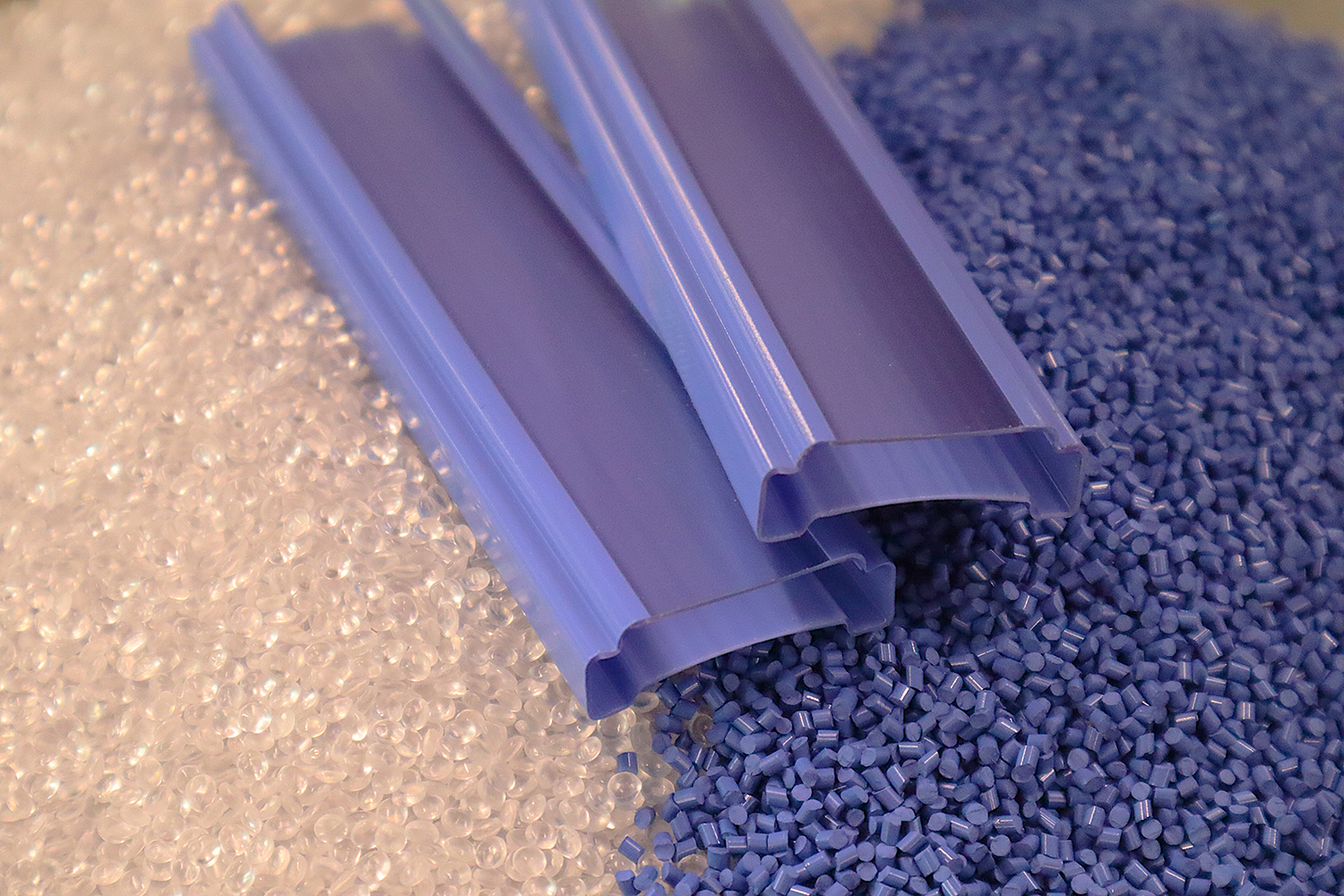

Layering Thermoplastics

Co-extrusion is a manufacturing process in which two or more different polymers are extruded through a single die to form one composite product. These polymers often have varying properties which allow the final product to have unique functionalities. This process can be advantageous for encapsulating a product with UV/Chemical protection or if a soft inner core is necessary for flexibility. It is also ideal for achieving color changes in a product allowing for clear site windows or semi-transparent sections for light diffusion. Many industries use co-extrusion to take advantage of the properties that each material can offer, combining them in ways that would be difficult or costly to achieve with single-material parts.

Contact us today with your product specifications and speak with our on-site engineering team, who will collaborate with you to manufacture your product at our facility!