Packaging comprises around 31% of global plastic usage. Of course, not all of this packaging is the same. It comes in many shapes and sizes and is created through a variety of plastic molding techniques.

Wondering which types of plastic molding exist out there? Curious about which one you should use for your packaging? Then keep reading. Here are your options for plastic molding technology.

Extrusion Molding

Up first is extrusion molding. This is a form of molding where a die is used to shape the finished product. With other forms of plastic molding, a mold is used to create this shape.

In particular, extrusion molding involves pushing hot plastic through the die so as to give the plastic the same shape as the inside of the die.

This allows extrusion molding to excel in the manufacture of hollow-bodied entities. These run the gamut from straws to tubes to pipes and more. Note, however, that these aren’t the only types of plastic products that extrusion molding is good for.

Extrusion molding is also effective at producing parts with continuous lengths, not to mention identical cross-sections. Want T or U-shaped plastics? Extrusion molding can be used to shape those as well.

This is a fairly cheap molding process to carry out. Upfront equipment costs are low, as is the cost of the process itself. This is because extrusion molded products are quite simple in their characteristics.

It’s important to note that extrusion molding isn’t great for exceedingly complex and intricate shapes. It essentially requires the finished product to possess the same shape from point A to point Z. As such, it’s only sufficient for broad plastic molding purposes.

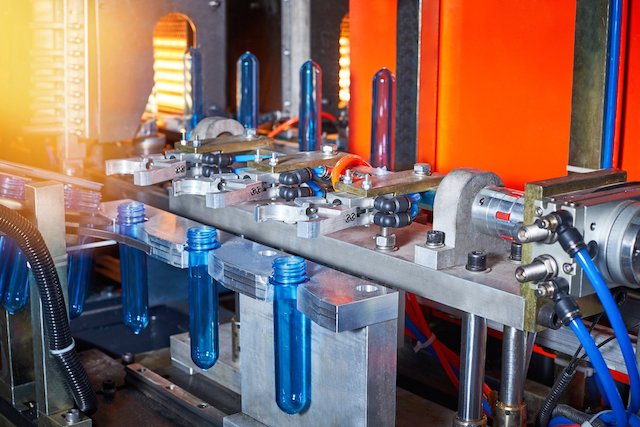

Blow Molding

Up next is blow molding. This involves using a specialized machine to blow air on a heated piece of plastic. The air shapes the plastic in the desired manner until it takes its final form. Once it has, the machine cools the plastic and ejects it, ready for use.

Like extrusion molding, blow molding excels at manufacturing hollow-bodied plastic entities. That said, the products it’s used for typically possess thinner walls. Some of the products that blow molding is commonly used to create include bottles, barrels, and storage containers.

Note, however, that, like extrusion molding, blow molding isn’t good for intricate and complex pieces. It’s used for broader and simpler shapes overall.

Injection Molding

Another form of plastic molding to consider is injection molding. This involves injecting hot plastic into steel molds. The molds possess the desired shape and, so, when the plastic cools, it possesses that shape as well.

This form of molding can be used for just about everything. It serves both basic and complex designs. However, if you’re using it for complex designs, you need to possess a thorough understanding of plastic characteristics in order to create the products desired.

Injection molding is great for situations in which you must mass produce a like item. The machine works quickly and efficiently, and rarely makes manufacturing mistakes once primed.

In truth, injection molding isn’t a great choice for one-off projects. This is because the molds used in the injection molding process take months to perfect. Not to mention, they’re highly expensive.

If you’re looking to manufacture many products at a low overall price, injection molding might very well be the solution for you. Otherwise, in the vast majority of cases, you should turn to a different style of molding.

Compression Molding

Compression molding is the process of putting liquid plastic into a mold, closing the mold, and then squeezing the mold until the plastic has reached a solid state. By the end of the process, the plastic has assumed the shape of the mold it was put in.

Note that, due to the high heat associated with compression molding, the finished product is also cured. In other words, it’s extremely tough and durable, capable of taking on substantial wear and tear.

This form of molding is capable of creating strong and complex plastic entities. That said, it doesn’t reach the level of complexity facilitated by injection molding.

Compression molded parts are used in products of all kinds, from automobile components to industrial components to kitchen appliances and much more. If you need a strong and durable product, compression molding is a good way to go.

Rotational Molding

Sometimes called rotomolding, rotational molding involves rotating the mold during molding so as to create desired shapes and contours. The hot plastic takes shape as the mold is rotated, as centrifugal force causes the resin in the mold to carve a shape out evenly. Eventually, the hot plastic cools off, at which point the item is ready for use.

Rotational molding is most frequently used in the manufacture of large and hollow items. For instance, you might use rotational molding in the creation of a liquid storage tank. Or, you might use it to create boat hulls, dog houses, and car parts.

This is a form of molding that wastes very little product. Almost all of the plastic put in the mold ends up being used. That small amount of plastic that doesn’t get used ends up being used for other items. In short, rotational molding is incredibly efficient.

Rotational molding doesn’t quite provide the precision of injection molding. However, it can still facilitate the production of some complex and intricate items.

The major drawback to rotational molding is that it’s slow. It takes a long time for a rotational molding project to finish. Because of this, rotational molding is typically only used for custom work, not assembly line work.

There Are All Types of Plastic Molding

As you can see, there are all types of plastic molding. Regardless of what you’re hoping to achieve with plastics, there’s a molding method that will accommodate you.

Interested in reaping the benefits of extrusion molding? If so, we here at Petro Packaging Company are the people to see. We provide custom plastic extrusions of all kinds. Regardless of your needs, we have you covered.

Contact us today to discuss your plastic molding needs!