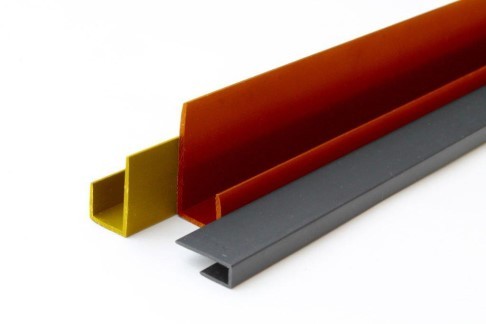

Plastic channels are polymers structures with profiles that extrude linearly. The cross-sectional shape of these channels is constant across their axis. These structures are long and narrow with a relatively short depth, making them useful in several applications. They can also serve as a guide, sealant, connector, panel, insulator and structural material. They are a common feature in construction material and electronic appliances.

Plastic channels are available in different extruded profiles, including C-, H-, J-, L- and U-channels, all of which Petro Packaging Company manufacturers. You can also request custom plastic channels, specifying dimensions and shapes that fit your needs. In this article, we discuss the process of plastic extrusion and the applications of the plastic J-channel extrusions we make using this process.

Plastic Extrusion Process

Plastic extrusion is a manufacturing process that converts raw plastic material in plastic products with a continuous profile. The process uses heat to form new or recycled plastic into a specific shape. Examples of plastic products made using plastic extrusion include tubing, piping, deck railings, weather stripping, fencing, wire insulation, thermoplastic coatings, plastic sheeting and plastic films.

The raw plastic materials used in plastic extrusion include ABS, nylon, elastomers, PVC, etc. These materials determine the properties of the final product. Petro Packaging Company manufacturers plastic J-channel extrusions using specialty materials, including but not limited to PETG copolymer (polyethylene terephthalate glycol), Tenite™ CAB (cellulose acetate butyrate), and clear Tenite™ CAP (cellulose acetate propionate) plastic.

Plastic J-channel extrusions made from PETG copolymer and Tenite™ CAB have several remarkable properties, including chemical resistance, crystal clarity, easy bonding and easy fabrication. We prepackage standard plastic channels in 6-foot lengths so they are available for quick orders.

The specifications of your projects determine the polymer and components we use in the extruders. During the extrusion process, the polymer is directed toward heated components on the front of the extruder. There, the polymer pushes through an opening that matches the customer’s specifications.

After leaving the extruder, the polymer passes through a tool that shapes it into the intended profile. In the case of the plastic J-channel extrusion, the profile takes the J-shaped form. Finally, we ensure that the size and shape of the material matches the customer’s requirements.

The tooling used determines the shape and size of plastic products made using the extrusion method. This is because the process involves the melting of plastic raw materials. Furthermore, the skills and expertise of the operator also plays a role in the quality of the final product. For that reason, Petro Packaging Company hires only the best machine operators and takes them through extensive training.

Leading manufacturers of plastic products typically equip their extrusion lines with takeoff units to exert tension on the polymer as it leaves the extruder. Doing so increases the speed of the extrusion process and ensures that final plastic channel extrusion takes the correct shape.

They cut the parts at the end of the extrusion equipment into predefined lengths and package them into spools. Once we finish making the plastic channels, we package them into suitable containers for shipping.Benefits of Plastic Extrusion

- High Volume, High Speed, Low Cost. Plastic extrusion produces large volumes of parts efficiently, cost-effectively and with minimal wastage.

- Versatility. Plastic extrusion is highly versatile, enabling us to be creative and provide plastic products of varying shapes, hardness, thickness, texture, color and size.

- Alterations. Plastic extrusion lets us manipulate plastics after extrusion while they are still hot. So, we can use various dies, shoes and rollers to make alterations on the fly.

- Customization. Plastic extrusion lets us produce plastic products with complex shapes of varying color, texture, thickness, etc. We can also introduce additives to improve properties, such as fire resistance and durability.

Uses Of Plastic J-Channel Extrusions

Trim Seals

Trim seals provide airtight sealing and insulation by filling the space between two mating surfaces for large and insulated containers, freezers, refrigerator doors, compartments, car passenger and tailgate doors, and more. In this case, the plastic J-channel extrusion function serves as a gasket. It may comprise coextruded layers of vinyl- or rubber-coated polymers that prevent rattling, noise or corrosion. Considerations to make when choosing trim seals include service temperatures, grip size, grip strength and exposure to moisture or vibration.

Edge Trims

You can improve the ergonomics and safety of furniture and appliance by using J-shaped edge trims to cover the rough or sharp edges. This benefit is double-edged as edge trims also protect the edges of the furniture and appliances from damage, making them last longer. Furthermore, the channels can improve the aesthetics of these items. Edge trims can cover the edges of ceramic, metal and wood on furniture, windows, car seats, ceilings, tables, shelves, cabinets and machinery guards.

Cable Raceway

Plastic J-channel extrusion is suitable for making cable raceways used to organize, route and support electrical wiring and cables. The channel provides an enclosed track for the cables and wires to pass. It prolongs the lifespan of the cable and wiring by shielding them from abrasion, weathering and heat. By taking cables and wiring out of sights, cable raceways declutter spaces and remove safety hazards from wiring and cables. You can use these raceways outdoors or indoors by using self-adhesive backing to mount them on tables, desks, floors, walls, poles and ceilings.

Plastic Rails

You can use plastic J-channel extrusions to make plastic rails for several purposes, such as price tag moldings, panel holder, dust cover, etc. Price tag molding, in particular, are common in warehouses, grocery stores and retail stores, where they are sued to organize products on shelves.

Slotted Cable Raceways

Slotted cable raceways have slots on the side through which wiring can pass. They improve convenience and accessibility because you can plug in an electronic device or appliance at any point on the cable. They are suitable for several commercial and residential applications because electrical wiring can branch out from any side.

Wire Guards

Plastic J-channel extrusions can serve as effective wire guards in outdoor applications. You can mount the channels on floors or poles to protect communication and electrical wiring from damage. Straps or clamps typically support wire guards from plastic J-channel extrusion because self-adhesive backing is not appropriate for outdoor applications.

Superior Plastic J-Channel Extrusions

Petro Packaging Company specializes in making high-quality plastic J-channel extrusions for several applications. Contact Petro Packaging Company today for free consultation or to request a quote or sample.