Over the last half a century, the generation of plastic has skyrocketed by thousands of tons.

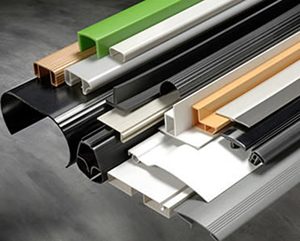

This material has become an integral part of the development of our society and offers simple solutions to our everyday jobs. Like our plastic extrusions that benefit multiple industries and help businesses across the globe daily.

If you’re a business owner or interested in learning more, then keep reading!

We’re going to explore our plastic c channel extrusion and talk about what it is, how it’s made, and how it could help you.

What Are Plastic C Channel Extrusions?

First off, what are plastic c channel extrusions?

Plastic C channel extrusions are an open-faced plastic holder that has sides that twist in. This creates the “c” shape, hence its name. This shape allows users to slip labels, cards, or displays into a structure and then kept in place.

The application of this style of extrusion is to display items. For example, a nameplate on the outside of an office door, business card holders, or sign displays in retail stores. They offer great practical use and are reusable. The design allows for easy insert and removal, and the material gives it long-lasting durability.

You can customize the holding mechanics, channel size, and color to your specific needs.

How Are They Made?

How Are They Made?

The plastic extrusion process involves a highly technical machine using gravity to pour melted raw plastic into the barrel of an extruder. There is also an injection method where the machine injects liquid plastic into a mold. With an injection, instead of the extrusion being extracted through a die, it is extracted from a die.

The die is where the actual plastic is formed and shaped. The design of the die must encourage even distribution of the plastic throughout the cylindrical profile.

If done incorrectly, the product will experience unnecessary stresses that cause warping and invalidity.

Once molded, it goes through a water bath to cool and set the shape of the plastic channel. It’s a specific type of shielded bath that’s designed to ensure the plastic’s shape is held while cooling and doesn’t fall apart.

You can add extras, like color and UV inhibitors, in either a liquid or pellet form depending on the specifications.

The Materials We Use

There many types of plastic and resin that extruded plastic c channels are made from. Below are the various thermoplastics we specialize in.

Thermoplastics are plastics with a low melting point and are easily fabricated into different products.

PETG Copolymer

Or Polyethylene Terephthalate Glycol, is a recyclable plastic that releases no toxic fumes or odors. It is transparent and has a high resistance to chemicals and impact. It can be used as a film for food and medical packaging, or injected and made into toys and devices. It can also be extruded into bottles and much more.

This is the type of plastic we use for our stock plastic c channel extrusions.

Tenite CAB

Or Cellulose Acetate Butyrate, yields a lower plasticizer rate. Meaning, it has a higher heat resistance and better dimensional stability. This is a common choice for profile extrusions, containers, and hardware packaging. It does release an odor, but it’s tougher than its counterparts.

Clear Tenite CAP

Or Cellulose Acetate Propionate, is a popular choice for manufacturing point-of-purchase, packaging, and profiles. This is an FDA approved counterpart to the above Tenite plastic. Hinted by its name, it’s a transparent material with excellent impact resistance. However, it does have a higher plasticizer rate than the Tenite CAB.

Other Plastic C Channel Materials

Other common thermoplastics may include:

Rigid PVC

Or polyvinyl chloride, a very strong and stiff budget-friendly plastic that’s moldable and bonds well with adhesives. This thermoplastic is easy to weld and is often used in constructing tanks, valves, and various piping systems.

Polypropylene

One of the most popular strains of plastic. It has extreme resistance at room temperature. It’s common in the automotive industry and textiles, but most popular for living hinges.

ABS

Acrylonitrile Butadiene Styrene. This possesses strong resistance to corrosive chemicals as well as impact. It has a low melting temperature and is relatively inexpensive. It’s used for lego toys, wall sockets, and keyboards. In recent years it’s been adapted for the use of 3D printing.

Uses Of Plastic C Channel Extrusions

There are various types of plastic extrusions that all serve many different purposes. However, c channel extrusions serve the purpose of helping:

- Retail Displays

- Store Fixtures

- Visual Merchandising

- Lighting

Display signs, nameplates, and much more will benefit from a c channel extrusion. And more importantly, items that need to change will benefit. That’s what makes this model unique. The function of this channel is to hold things securely, while also allowing users to change the item when necessary.

Another popular model is the plastic h channel extrusion. If you’re interested in the other models of channels, we have stock extrusions of many types.

The Benefit

The benefit of using this product, especially a customized one, is you not only recruit a useful tool, but you invest in a durable product that you can use over and over again.

With custom plastic c channel extrusions, you can create the perfect extrusion that fits your business’s needs, and know you won’t have to replace it for years to come.

Petro Packaging: Handling Your Plastic Needs!

Plastic c channel extrusions are a fundamental tool when it comes to business. Being able to display cards and signs is crucial to the representation of your business and deserves quality craftmanship.

Here at Petro Packaging, you can trust we’ll work with you to create the perfect tools.

We hope you found this article enlightening. If you have any questions, don’t hesitate to contact us. In the meantime, check out our blog for more insider information!

How Are They Made?

How Are They Made?