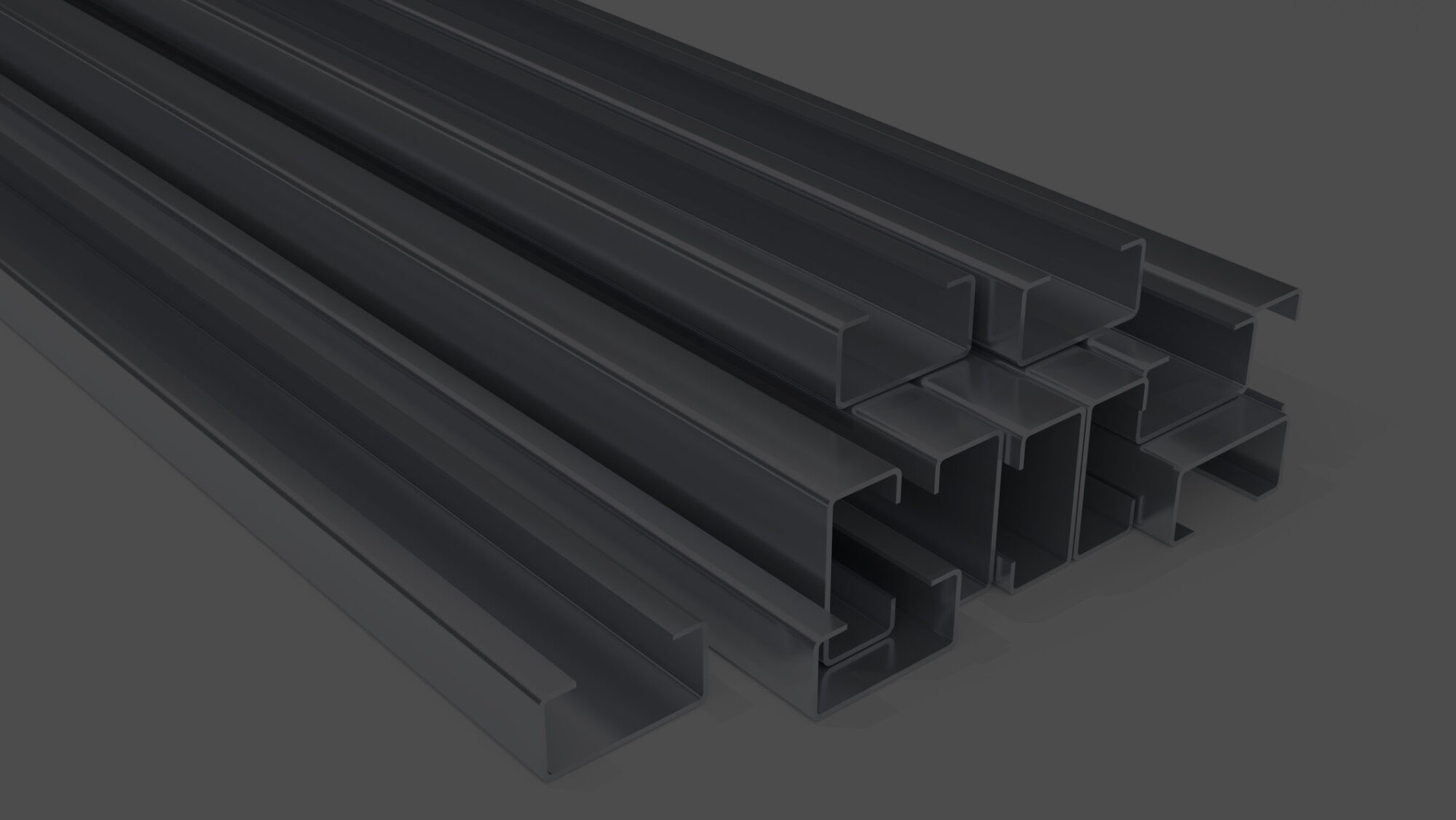

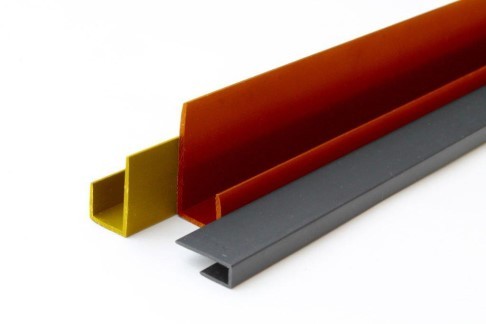

Plastic Joiner Extrusions are versatile and practical components that are used in a wide range of applications. They are extruded profiles designed to connect, join, or secure two or more panels together. These Joiners are typically designed for easy assembly and can be used in a variety of systems. From construction and automotive to medical and consumer goods, they play a crucial role in providing secure, efficient connections between parts.

Here are some common uses of Plastic Joiner Extrusions: