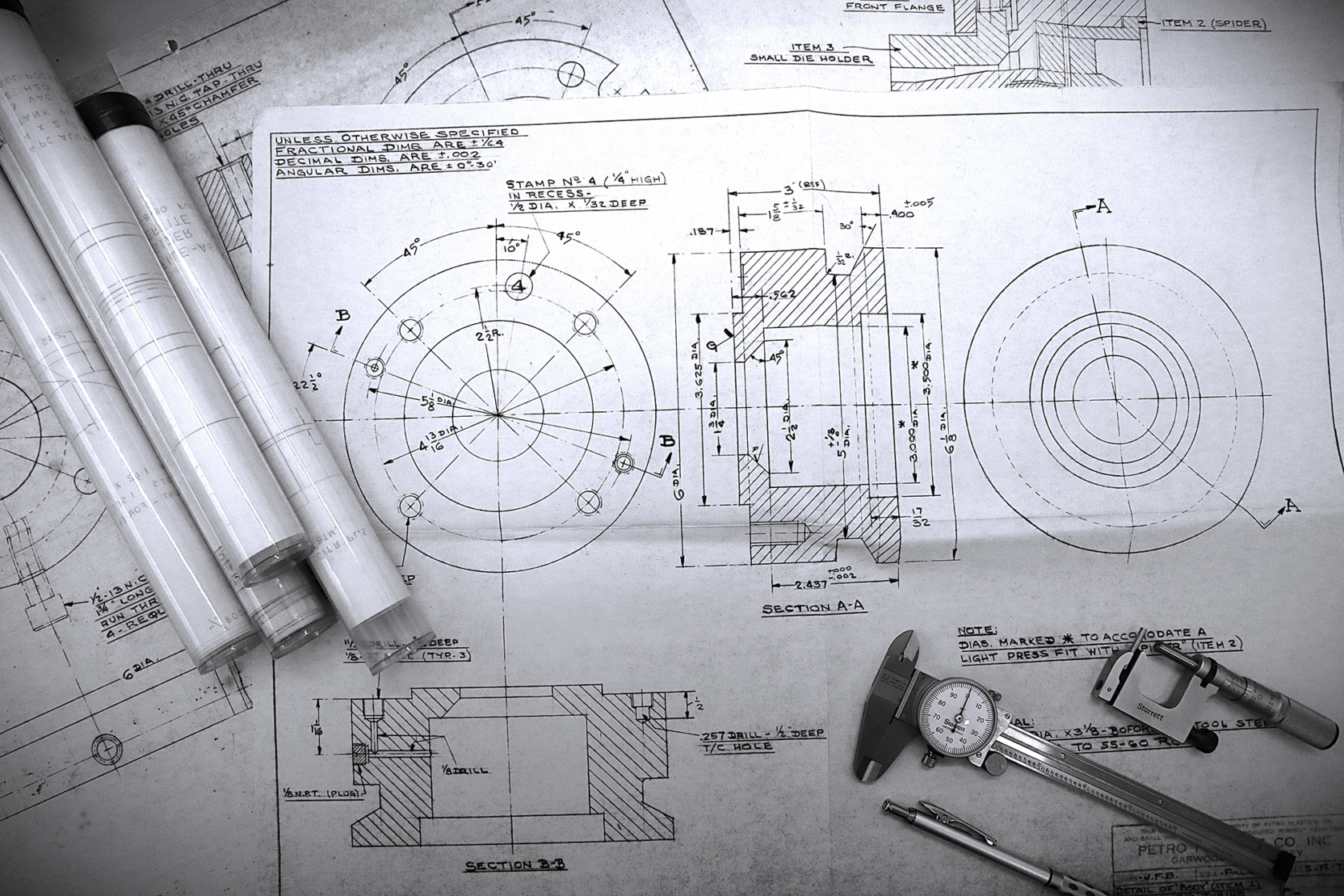

Plastic Extrusion Design Support & Dimensional Specs

Design analysis can offer valuable guidance to streamline production and improve the functionality of your product. Many design engineers familiar with other materials and manufacturing processes will often attribute tight dimensional expectations to the plastic extrusion process. While tolerances are absolutely necessary, over-constraining thermoplastic products can lead to slower production and an increase in non-conforming product resulting in much higher costs to the customer. Thermoplastic materials have unique properties that cause minor variations during the extrusion process, and it is for this reason special consideration must be given to dimensional tolerance control.

Often, an analysis of the end use of the profile can determine which features and dimensions are critical to its functionality. In most cases, tight tolerances only need to be applied to those critical locations. We’ll gladly make our engineering department available for you to determine the optimal tolerance choices for your product to ensure its function and quality while reducing its cost.