In a competitive industrial environment, how you move materials inside your facility can be just as important as how you make them. That’s why more forward-thinking manufacturers are turning to pneumatic tube systems —an advanced, efficient solution for rapid, safe, and space-saving material transport.

At Petro Packaging Co. Inc, we support the growing demand for pneumatic transport by providing high-performance plastic tubing and custom components for pneumatic systems. Whether you’re designing a new system or upgrading an existing one, our extrusion expertise ensures your infrastructure is built for speed, durability, and precision.

What Are Pneumatic Tube Systems?

What Are Pneumatic Tube Systems?

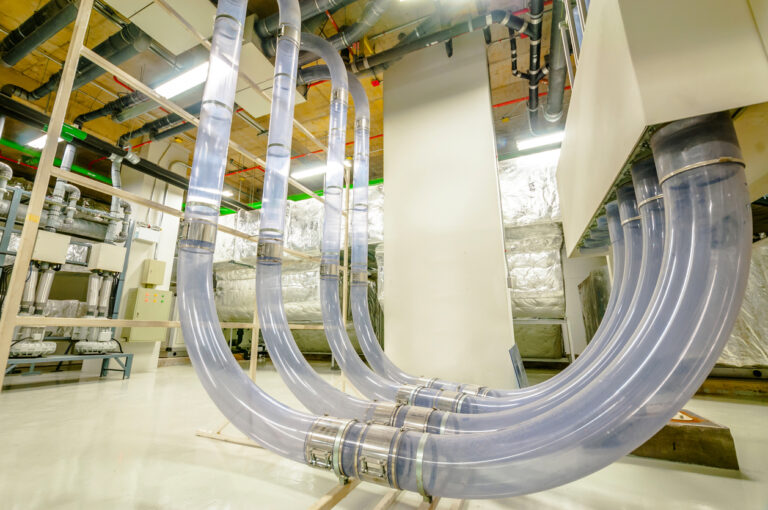

Pneumatic tube systems (PTS) use air pressure or vacuum to move sealed carriers through a network of tubes. These systems are ideal for transporting parts, documents, samples, or materials across your facility—quickly, securely, and without tying up valuable labor or floor space.

Each system includes:

- Heavy wall plastic tubes extruded to tight tolerances

- Carriers to hold materials

- Blowers or vacuums to create airflow

- Diverters to switch routes

- Send/receive stations for loading and unloading

Unlike conveyors, PTS can move items horizontally, vertically, and around corners, adapting seamlessly to complex factory layouts.

Key Advantages of Pneumatic Tube Systems

Increase Throughput and Speed – Materials travel at speeds up to 25 feet per second, dramatically reducing wait times between production steps. In pharmaceutical and electronics plants, that can mean faster approvals, fewer delays, and higher output.

Improve Safety – With fewer employees moving materials by hand, you reduce the risk of injuries, spills, and exposure to sensitive or hazardous items. Sealed tubes also minimize contamination risks in sterile environments.

Maximize Facility Space – Because tubes are mounted overhead or integrated into walls, PTS free up floor space for machinery, inventory, or people—unlike conveyor belts that take up valuable real estate.

Scale with Your Growth –Today’s PTS are modular and customizable. You can expand routes, add new drop-off points, or integrate with automation and MES/ERP systems—without major facility redesigns.

Industries Benefiting from Pneumatic Tube Systems

Our tubing solutions are used across industries where precision, cleanliness, and speed matter most:

- Pharmaceuticals: Send test samples, documents, or raw materials securely between labs and production zones.

- Electronics: Transport static-sensitive components in clean environments using antistatic tubing options.

- Food Processing: Move quality control samples without compromising sanitation protocols.

- Retail/Banking: Securely transport cash and receipts between registers and safe rooms.

- Manufacturing & Assembly: Eliminate wasted motion and labor by automating internal logistics.

Custom Plastic Tubing for Pneumatic Systems

As a trusted partner to industrial OEMs and systems integrators, we specialize in extruding custom plastic tubing designed for pneumatic use:

- Material Options: butyrate, propionate, polycarbonate, polyethylene, and more—selected for chemical resistance, durability, and pressure performance.

- Custom Diameters: Precision-extruded tubing from narrow bore to large-diameter, based on your airspeed, carrier size, or system pressure requirements.

- Additives & Features: UV resistance, antistatic properties, flame retardants, or custom colors for route identification.

- Flexible or Rigid: Depending on layout needs and environmental conditions, we provide tubing with the right combination of rigidity and bend tolerance.

We help you design a system that not only works but works better—built to your specs and backed by decades of extrusion expertise.

Cost & ROI: Why It’s Worth It

While pneumatic tube systems require an upfront investment, they offer substantial returns that continue to pay off:

- Lower labor costs by reducing manual handling

- Faster workflows and less production downtime

- Fewer handling-related product losses

- Improved safety and fewer injury claims

- Space savings that support lean manufacturing goals

Most operations see a full return on investment in 12 to 36 months—with productivity gains continuing for years to come.

Let’s Build Your Pneumatic Transport System Right

From tube to system, it starts with the right materials. At Petro Packaging Co, Inc, we don’t just supply tubing—we engineer plastic solutions that are tailored to your process, industry, and performance needs.

Whether you’re a system integrator looking for an extrusion partner or a plant manager exploring new transport options, we’re ready to help you design a smarter material movement strategy.

Contact us today to request a quote or discuss your project with one of our extrusion experts!